|

|

Post by vikx on Dec 10, 2013 23:03:49 GMT -8

Thanks Merle, great ideas.

I've been waiting to post more pictures but we've had a cold spell and my hands fail me when it's too chilly. Been below freezing all week. At this point, I've used narrow strips to form the curve and bought veneer. Too cold to glue, of course... warming to 47 by the end of the week, maybe...

I really appreciate the steam pipe idea and bending the ply over the outside. I've still got one sheet of bendy ply and the front cabinet needs to be done... Hard to kerf 1/8 inch ply, tho.

|

|

supermerle

Member

No matter where you go, there you are.

No matter where you go, there you are.

Posts: 47

Likes: 6

1964 Shasta 1500

Currently Offline

|

Post by supermerle on Dec 11, 2013 11:44:33 GMT -8

V

You might just use an exacto knife and cut some "V"'s on the back side to kerf it?

|

|

|

|

Post by universalexports on Dec 11, 2013 18:51:06 GMT -8

interested to see how this turns out, I have to build the same thing.

|

|

|

|

Post by vikx on Dec 11, 2013 23:03:21 GMT -8

I'll try a test piece with the Exacto... I won't forget to post pix, just too d*** cold...

|

|

supermerle

Member

No matter where you go, there you are.

No matter where you go, there you are.

Posts: 47

Likes: 6

1964 Shasta 1500

Currently Offline

|

Post by supermerle on Dec 12, 2013 6:11:07 GMT -8

Vikx

I was also thinking you might get a spray bottle and fill it with water and just mist the back side of the plyw two help create stream to help the bendind process.

|

|

supermerle

Member

No matter where you go, there you are.

No matter where you go, there you are.

Posts: 47

Likes: 6

1964 Shasta 1500

Currently Offline

|

Post by supermerle on Dec 12, 2013 6:53:06 GMT -8

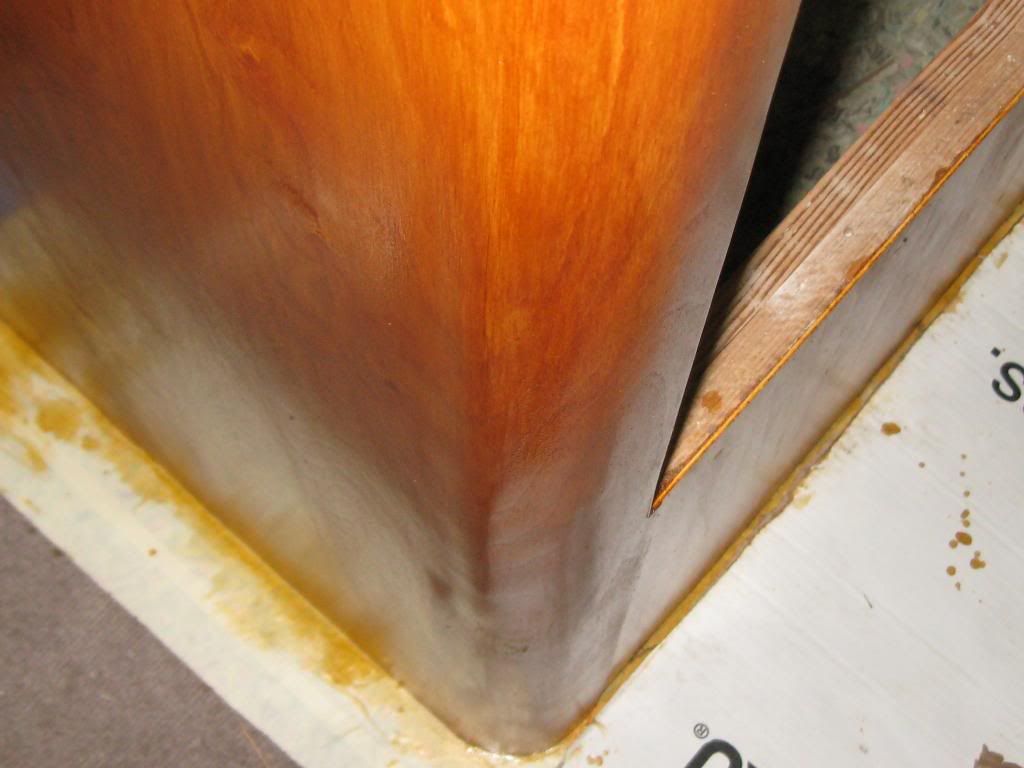

Vikx Here's a picture of the scroll area that I have to bend the rib to match. I do this using the copper pipe and mapps gas bottle and the spray bottle. This on a smaller scale but if you rig up using larger and longer stuff you should be in good shape to get your bends? Go slow and the wood will bend. Look up volin and mandolin site's and you should get some ideas. Good luck.  |

|

|

|

Post by vikx on Dec 12, 2013 22:41:33 GMT -8

Wow, Merle, that's tight...

The only concern I have is the plywood place said the glue would fail with steam. I'm gonna do it anyway, on a test piece.

Finally broke the freeze!

|

|

SusieQ

Global Moderator

Posts: 4,781

Likes: 1,197

'62 Shasta Compact

Currently Offline

|

Post by SusieQ on Dec 13, 2013 0:42:21 GMT -8

Vikx, I thought about the steam pipe when I first read about your problem. I know it's on a much smaller scale but that is how they get the curve in the sides of stringed instruments. Of course, a fine instrument wouldn't be plywood but cheap ones are. I still have my first guitar which originally came from a Spiegel catalog many, many years ago, probably the age of my Shasta. I'm pretty sure it is all plywood. I also have some cheap ukes that are veneered mahogany plywood (and expensive laminated ones). But if you are going to veneer, I would think you would need to bend it first. I've never tried it myself, but I've watched lots of videos. (I sound like a commercial) And then I bought my sides already bent. But it's on my list.  And the way they get the curve to stay, they clamp it to frame in the correct shape and let it dry. And now you know. I'm sure you always wondered how guitars got their curves. And one more thing, be careful, because I have seen them scorch the wood on a few occasions. |

|

supermerle

Member

No matter where you go, there you are.

No matter where you go, there you are.

Posts: 47

Likes: 6

1964 Shasta 1500

Currently Offline

|

Post by supermerle on Dec 13, 2013 7:38:18 GMT -8

V

Yeah, SusieQ is right on what she said. Once you bend the wood leave it clamped until it dryes and support the front side with something rigid like thin metal or plastic, or etc. Good luck.

|

|

|

|

Post by vikx on Dec 15, 2013 11:25:55 GMT -8

Curved Cabinets, Part II OK, here's what has been done so far: The cabinet curve was filled in with shaped wood, then strips were added to match the side panel.    The strips were sanded as smooth and round as possible:  Contact Cement was applied to the closet and veneer. We heated the shop with a propane bullet heater.   Lots of clamps:  We sealed with shellac.  One little glitch, not bad for a first try:  Looks pretty good:  |

|

|

|

Post by vikx on Dec 15, 2013 11:32:08 GMT -8

And the story continues: Unfortunately, the veneer didn't stay smooth. There are some ripples on the flat panel (not there 24 hours ago). I'm guessing it's just too cold to be veneering anything... I was trying to "finish" the closet so that the welting could be attached, then go on with ceiling panels. The front cabinet and two kitchen uppers can be done in the house. Not sure what to do about the lower kitchen cabinet, it is already in place.   The front cabinet original curvy wood is in good enough condition to veneer. More later. |

|

|

|

Post by vikx on Dec 15, 2013 11:34:32 GMT -8

Ideas welcome.

The curve was the easy part... Needless to say, a huge disappointment with the ripples. Hopefully my learning curve will help us all.

I'm going to try a heat gun today but don't have high hopes...

|

|

|

|

Post by bigbill on Dec 15, 2013 11:34:42 GMT -8

I believe that I could live with it. Looks good to me.

|

|

|

|

Post by bigbill on Dec 15, 2013 11:39:39 GMT -8

On your ripples could you use a hypo needle and inject some glue in them then clamp them in place for a day or two. Then touch up the finish.

|

|

|

|

Post by vikx on Dec 15, 2013 11:49:35 GMT -8

LOL BigBill, I thought of the needle and also drilling a hole in the back to insert spray foam... That was for the first glitch, not the entire panel.

I believe it is possible to clamp sections and glue may be a solution.

Will try for photos today, VERY difficult to get the ripples to show. I can feel them, that's for sure. Grrr.

|

|