Designing a solar/battery system for boondocking

Aug 1, 2020 19:11:50 GMT -8

vikx, wisconsinjoe, and 7 more like this

Post by datac on Aug 1, 2020 19:11:50 GMT -8

I've had several folks DM me asking for more information about my LiIon battery/solar setup, so I thought I'd be better off starting a thread.

First off, as with all things, I don't claim to be an expert in any way, but I'll share what I've learned in the hopes that someone else might find it useful.

I knew I wanted a refrigerator rather than an icebox, having done iceboxes for years. Evaporation (propane) refrigerators have a bunch of quirks, being very slow to cool, requiring fairly accurate leveling, throwing out a fair amount of heat and requiring significant venting. A giant vent next to the front door doesn't exactly thrill me. They're also not cheap. Initially I planned on a Dometic icebox conversion kit, but they're around $1k or more, and, as I discovered, the cooling plates won't actually fit inside iceboxes of the dimensions common to old trailers anyway. Assuming I even had an old trailer icebox, which was going to cost more $.

Long backstory, but 35 years ago my folks lived on a sailboat in Baja, and my father built a van to haul supplies and equipment back and forth when they made the annual commute home to Oregon for the summer. Spending a bunch of time in rural Mexico, he wanted to keep it as low-key as he could, so he started with a new E-350 window van instead of a conversion, added a pull-out bed and a kitchen that fit under the windows, around 300w of solar panels on the roof, and a set of giant lead-acid golf cart batteries to power the refrigerator (he didn't want to add propane or have any vents visible that would mark it as an RV). He kept the van for years even after selling the boat, and often camped next to me on our frequent weekends at Portland International Raceway. I became convinced that the solar powered refrigerator, always stocked with cold drinks, was the very pinnacle of Western civilization. Anyway...

First off, if you're planning on a setup for boondocking, you'll need to know your power requirements. Choose 12v over 110v wherever you economically can, since drawing 110v through an inverter (a device which converts 12v DC to 110v AC) takes more power than just running 12v to begin with, as the inverter introduces losses of its own. Keep in mind that just because it's less efficient doesn't mean that it doesn't still make better economical sense, though, but we'll come back to that.

Using my setup as an example, I wanted to keep the appearance of my '57 Cardinal as close to original as possible. I kept the original 110v light fixtures, but substituted readily available E26/E27 12v LED lightbulbs, which look and fit much like the original incandescent bulbs. These only draw 3 watts each, I have four, which means that all four together draw 12 watts. If I run all four for eight hours a day (very unlikely, but I like to be conservative), that's 3w * 4 bulbs * 8 hours or 96 watt hours per day. Battery capacity is measured in amp hours, so you'll need to convert between watt hours and amp hours using the formula (Wh)/(V)=(Ah), so 96 watt hours divided by 12v = 8 amp hours. I'd draw 8 amp hours of battery for every eight hours I kept all four lights on. Easy enough! Use the same formula to calculate all of the power consumption from your 12v devices.

So you need 91 amp hours of battery capacity for every 24 hours you want to run, right? Not so fast. Lead acid batteries, the kind used in your car and the cheapest and most popular kind used in RVs, will suffer permanent damage if discharged below 50%, so to safely provide 91 amp hours a day you'd actually need 182 amp hours of capacity. This is not the case for lithium ion variants, which can safely and repeatedly be discharged to nearly zero without damage. Basically, when looking at lead-acid batteries, you'll need to double both the price and weight when comparing them against lithium ion batteries. While it's true that lithium ion batteries are much more expensive, there are other advantages which may make them the more attractive choice. A high quality 100AH lithium iron phosphate battery costs just under $1,000, weighs around 25lbs, and will likely outlive your trailer. An equivalent capacity lead-acid battery would need to have 200AH, costs around $400, weights 120lbs or more, and in practice has a service life of around 5 years, assuming it's not stored in a partially discharged state, discharged below 50%, etc. etc. Lead acid batteries also exhibit a reduction in capacity both as they age and as they go through more charge/discharge cycles, a characteristic not shared with lithium ion batteries. To add to the fun, lead-acid batteries also emit flammable gases, so they need to be located where they can be safely vented outside. That's why they're often found in tongue boxes.

Did I mention that that lead-acid battery weighs nearly 100lb more? That's not trivial in a small vintage trailer. For 200AH of available capacity, it's 50lbs vs. 240lbs.

OK, so we've established that I need a minimum of either roughly 100AH of lithium ion battery or 200AH of lead-acid battery to camp for 24 hours. Let's talk a bit more about inverters, the device that lets you run 110v loads on 12v.

First off, for geekly reasons I won't get into here, 110v AC power has a nice clean wave form called a sine wave. DC power does not. Cheaper inverters roughly approximate that 110v sine wave, kinda, sorta, and some simple 110v loads are perfectly happy with that. These are called modified sine wave inverters. The other kind of inverter is more expensive, and is called a true sine wave inverter. The 110v power these provide closely resembles your household current and can be used for more sensitive loads, like electronic devices. Electric motors, like the one in your refrigerator compressor, may run on that cheaper inverter, but they'll do so less efficiently while generating more heat, and may ultimately have a reduced service life as a result. Other loads may fail to function at all, may behave oddly, may die a horrible death, or might work just fine. Don't mess around, for our purposes stick with a true sine wave inverter. Other factors in choosing an inverter are the capacity (wattage), efficiency, and the presence of a stand-by or sleep function. Keep in mind that capacity and efficiency are linked- buying an inverter with a higher capacity than you need means paying the price in increased power consumption. Smaller inverters are often 90-95% efficient or more, meaning you'll only need to add 5-10% of the load to operate the inverter. Larger inverters may be 70% efficient or less, which is going to dramatically increase your power consumption. Buy the smallest inverter that can reasonably support your anticipated 110v load, with one caveat- refrigerator compressors will draw anywhere from 3-8 times their stated wattage, sometimes more, at startup. My refrigerator draws around 80 watts when it's running. Even as it cycles on and off, as I watch on my Kill-A-Watt, I don't see a spike higher than 80 watts, as the increased load goes by so quickly that the meter doesn't have a chance to display it. I should be fine with a 300 watt inverter, right? If it were anything besides a big electric motor, probably, but in this instance the inverter would shut down in an overcurrent condition. To accommodate both this and the 110v load from the CPAPs, I actually need something closer to a 1000 watt inverter.

A sleep or standby function is also a useful feature in an inverter, especially in applications where power must always be available (like a refrigerator). Otherwise, it's common to just have an on-off switch- turn it on to fire up the microwave or the TV (things I would never, ever bring camping, btw), turn it off when you're done. The inverter draws power whenever it's on, whether or not there's a load present, and that can eat into your battery capacity pretty quickly. Inverters with a sleep or standby function power themselves off, wake up for a split second every few seconds to see if there's a load present, and turn themselves back on if there is. This significantly reduces their electricity consumption. The only catch here is that some very small loads may not be enough to wake up the inverter, and some refrigerators (rarely) may not check their own temperatures when there's no power present. Most inverters with a standby function allow you to adjust the trigger current draw to fix the first scenario, but since in our application we're not likely to have low current draw 110v devices in the first place it's not as critical. If you turn out to be unfortunate enough to have a refrigerator that needs constant power to function, there's a cheap and easy workaround. Velleman offers a very simple and inexpensive thermostatic switch- place the temp sensor in your fridge, and it'll operate a relay to turn on your inverter, all with very low current draw. Odds are excellent that that won't be necessary, but it's good to have a contingency plan.

OK, we've got our loads calculated, we've got our battery capacity figured out, we've selected an inverter, and now we're ready to talk about solar panels and charge controllers, since we'd like to do more than camp for one day at a time. A bunch of math aside, an excellent rule of thumb is to assume that, pretty much anywhere in North America, you'll be able to put 30 amp hours a day into your 12v battery for every 100 watts of solar panel. It'll be a bit higher in Yuma in the summer, a bit lower in Oregon in the winter, but not enough to matter unless your design is on a total knife-edge anyway. Don't do that. You'll also see folks talking about adjustable racks to precisely track angle of the sun so as to get maximum efficiency, but again, in practice this doesn't add up to more than a couple of percentage points, and if that's what it takes to make your system work you've got other problems with your design. To replace the 91 amp hours we anticipate drawing from our batteries every day, we'd need a minimum of 303 watts of solar panel capacity.

Rigid solar panels are the cheapest and most efficient, and ideally you'd mount them up off the roof to allow airflow underneath to keep them cool, which also increases efficiency. Unfortunately, all of that increases ugliness at an even higher rate, and if you were after maximum efficiency vs. beauty you wouldn't be working on a 60-70 year old trailer anyway, would you? Flexible solar panels, on the other hand, are ideal for the curved roofs on many vintage trailers, and can be completely invisible from the ground once installed. They're commonly installed to RV roofs with 3M VHB tape, sometimes with Eternabond around the edges. Being less efficient, your flexible panels will be somewhat larger than rigid panels for the same output, but generally not enough to cause issues. As with all things, manufacturers vary considerably in quality and durability, so you'll likely want to stick with a reputable manufacturer rather than the cheapest thing you find on Amazon. I chose a pair of Renogy 175w flexible panels for a total of 350 watts, which at an estimated 105 amp hours/day gives me a nice margin of error.

OK, on to the charge controller. Sure, you could just plug your panels straight into your battery, dumping in energy whether or not the battery was up to the job, but that's a bad idea for anything with more than a couple of watts of output. As added incentive, you'd also need to install a blocking diode anyway to keep your battery from discharging through your solar panels at night. 300+ watts is nothing to screw around with, so you'll need a charge controller. There are two different available technologies, since we can't make this too simple- PWM, or pulse wave modulation, and MPPT, or maximum power point tracker. Yeah, sounds complicated, but basically a PWM controller is just a fancy switch that flicks between on and off as needed by the battery, providing just above the battery voltage. This is a good, economical solution if the panels you've selected don't put out much more than battery voltage, say a maximum power voltage of 18v or so for a 12v battery.

An MPPT controller is a different animal. It intelligently drops the panel voltage down to whatever is required to efficiently charge the battery, sort of a smart DC-DC converter. As the voltage drops the current increases, which means increased efficiency- anywhere from 15% to a theoretical 20% more power can be harvested from the same panels, assuming that the panel voltage is significantly higher than the battery voltage. In this instance, the Renogy 175 watt panels operate at a maximum of 24.9v, so this is a good fit. Did I mention a 15-20% increase in harvestable energy?

First off, as with all things, I don't claim to be an expert in any way, but I'll share what I've learned in the hopes that someone else might find it useful.

I knew I wanted a refrigerator rather than an icebox, having done iceboxes for years. Evaporation (propane) refrigerators have a bunch of quirks, being very slow to cool, requiring fairly accurate leveling, throwing out a fair amount of heat and requiring significant venting. A giant vent next to the front door doesn't exactly thrill me. They're also not cheap. Initially I planned on a Dometic icebox conversion kit, but they're around $1k or more, and, as I discovered, the cooling plates won't actually fit inside iceboxes of the dimensions common to old trailers anyway. Assuming I even had an old trailer icebox, which was going to cost more $.

Long backstory, but 35 years ago my folks lived on a sailboat in Baja, and my father built a van to haul supplies and equipment back and forth when they made the annual commute home to Oregon for the summer. Spending a bunch of time in rural Mexico, he wanted to keep it as low-key as he could, so he started with a new E-350 window van instead of a conversion, added a pull-out bed and a kitchen that fit under the windows, around 300w of solar panels on the roof, and a set of giant lead-acid golf cart batteries to power the refrigerator (he didn't want to add propane or have any vents visible that would mark it as an RV). He kept the van for years even after selling the boat, and often camped next to me on our frequent weekends at Portland International Raceway. I became convinced that the solar powered refrigerator, always stocked with cold drinks, was the very pinnacle of Western civilization. Anyway...

First off, if you're planning on a setup for boondocking, you'll need to know your power requirements. Choose 12v over 110v wherever you economically can, since drawing 110v through an inverter (a device which converts 12v DC to 110v AC) takes more power than just running 12v to begin with, as the inverter introduces losses of its own. Keep in mind that just because it's less efficient doesn't mean that it doesn't still make better economical sense, though, but we'll come back to that.

Using my setup as an example, I wanted to keep the appearance of my '57 Cardinal as close to original as possible. I kept the original 110v light fixtures, but substituted readily available E26/E27 12v LED lightbulbs, which look and fit much like the original incandescent bulbs. These only draw 3 watts each, I have four, which means that all four together draw 12 watts. If I run all four for eight hours a day (very unlikely, but I like to be conservative), that's 3w * 4 bulbs * 8 hours or 96 watt hours per day. Battery capacity is measured in amp hours, so you'll need to convert between watt hours and amp hours using the formula (Wh)/(V)=(Ah), so 96 watt hours divided by 12v = 8 amp hours. I'd draw 8 amp hours of battery for every eight hours I kept all four lights on. Easy enough! Use the same formula to calculate all of the power consumption from your 12v devices.

On to the 110v devices that you might want to run. If the goal was absolute efficiency, you'd run everything at 12v, but economics may disagree. A 12v refrigerator is far, far more expensive than a 110v refrigerator, enough so that it may actually be cheaper to pay for the extra battery and solar capacity you'd need to support the 110v fridge running through an inverter vs buying a 12v refrigerator. Similarly, both my wife and I use CPAP machines, and we could buy the non-warranty voiding 12v power supplies for these at around $150 each, or just run the less efficient 110v power supplies through an inverter and accept the reduced efficiency. The math is up to you. Cosmetics may also be a concern, since newer 12v refrigerators may look out of place in your vintage trailer. In my case, I found a very pretty dorm-sized 110v fridge that ended up costing me around $70, and looks great in my trailer. You'll need to look at the total system- the cost of the appliance, the inverter (if necessary), and the battery and solar capacity to support each option before making your choice.

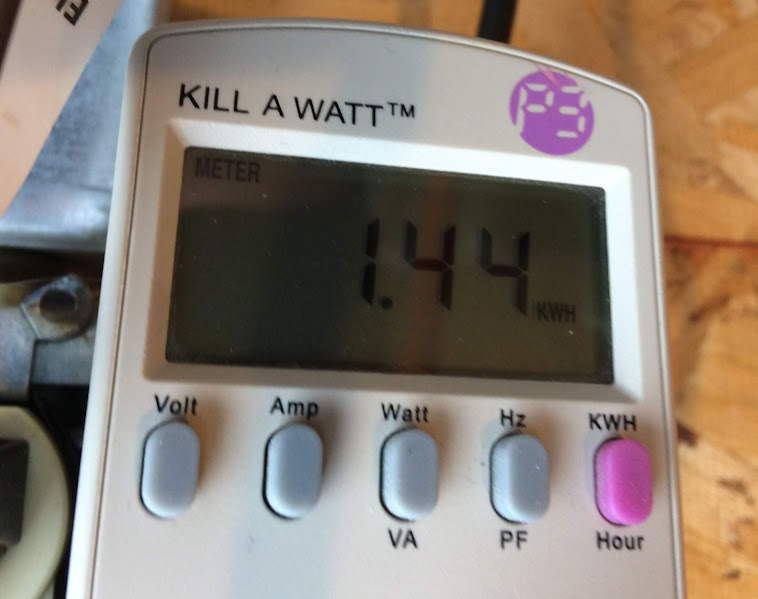

OK, how much battery do I need to run that? I highly recommend that you purchase a Kill-A-Watt meter, an inexpensive device that plugs into an outlet and monitors the power consumption going to whatever load you plug into it. Keep in mind that refrigerators do not run all of the time- they kick on and off like a furnace as the thermostat monitors the interior temperature. When you plug the refrigerator into your Kill-A-Watt, you're going to want to measure the power consumption over a long enough period that you can calculate your likely usage over 24 hours, either by leaving it plugged in for 24 hours or calculating by the number of hours you do leave it plugged in. Also consider that both the ambient temperature and the cooling load inside the refrigerator will impact your power usage, so you may want to do it with your refrigerator sitting in a hot garage and/or load it with warm pop to give you a worst-case scenario. Most inexpensive refrigerators end up running maybe 25% of the time, and sit idle with little to no current draw at other times. In my example, I left my refrigerator plugged in for 67.54 hours, as my Kill-A-Watt helpfully told me, with a total power consumption of 1.44 kilowatt hours, or 1440 watt hours.

Dividing my 1440 watt hours by 67.54 hours, I'm left with 21.32 watts per hour, or around 511.7 watt hours per 24 hour period. Great, that's 511.7 watt hours of 110v AC, which now I need to convert to amp hours of 12v DC. Again, applying (Wh)/(V)=(Ah), 511 watts divided by 12v is around 42.58 amp hours. Of course, we have to accommodate the losses introduced by the inverter (we'll come back to selecting an inverter and why that's important later), and let's say the particular inverter I've selected is 90% efficient. Dividing 42.58 amp hours by .9 gives us around 47.3 12v amp hours of battery capacity to operate this refrigerator for 24 hours. Using the same technique, I calculated that our power-hungry CPAPs each need around 15AH a night running through the same inverter. So far my power needs look like this:

| Load | Amp Hours |

| Lighting | 8 |

| Refrigerator | 48 |

| CPAPs | 30 |

| USB charger | 5 |

| Total | 91 |

So you need 91 amp hours of battery capacity for every 24 hours you want to run, right? Not so fast. Lead acid batteries, the kind used in your car and the cheapest and most popular kind used in RVs, will suffer permanent damage if discharged below 50%, so to safely provide 91 amp hours a day you'd actually need 182 amp hours of capacity. This is not the case for lithium ion variants, which can safely and repeatedly be discharged to nearly zero without damage. Basically, when looking at lead-acid batteries, you'll need to double both the price and weight when comparing them against lithium ion batteries. While it's true that lithium ion batteries are much more expensive, there are other advantages which may make them the more attractive choice. A high quality 100AH lithium iron phosphate battery costs just under $1,000, weighs around 25lbs, and will likely outlive your trailer. An equivalent capacity lead-acid battery would need to have 200AH, costs around $400, weights 120lbs or more, and in practice has a service life of around 5 years, assuming it's not stored in a partially discharged state, discharged below 50%, etc. etc. Lead acid batteries also exhibit a reduction in capacity both as they age and as they go through more charge/discharge cycles, a characteristic not shared with lithium ion batteries. To add to the fun, lead-acid batteries also emit flammable gases, so they need to be located where they can be safely vented outside. That's why they're often found in tongue boxes.

Did I mention that that lead-acid battery weighs nearly 100lb more? That's not trivial in a small vintage trailer. For 200AH of available capacity, it's 50lbs vs. 240lbs.

OK, so we've established that I need a minimum of either roughly 100AH of lithium ion battery or 200AH of lead-acid battery to camp for 24 hours. Let's talk a bit more about inverters, the device that lets you run 110v loads on 12v.

First off, for geekly reasons I won't get into here, 110v AC power has a nice clean wave form called a sine wave. DC power does not. Cheaper inverters roughly approximate that 110v sine wave, kinda, sorta, and some simple 110v loads are perfectly happy with that. These are called modified sine wave inverters. The other kind of inverter is more expensive, and is called a true sine wave inverter. The 110v power these provide closely resembles your household current and can be used for more sensitive loads, like electronic devices. Electric motors, like the one in your refrigerator compressor, may run on that cheaper inverter, but they'll do so less efficiently while generating more heat, and may ultimately have a reduced service life as a result. Other loads may fail to function at all, may behave oddly, may die a horrible death, or might work just fine. Don't mess around, for our purposes stick with a true sine wave inverter. Other factors in choosing an inverter are the capacity (wattage), efficiency, and the presence of a stand-by or sleep function. Keep in mind that capacity and efficiency are linked- buying an inverter with a higher capacity than you need means paying the price in increased power consumption. Smaller inverters are often 90-95% efficient or more, meaning you'll only need to add 5-10% of the load to operate the inverter. Larger inverters may be 70% efficient or less, which is going to dramatically increase your power consumption. Buy the smallest inverter that can reasonably support your anticipated 110v load, with one caveat- refrigerator compressors will draw anywhere from 3-8 times their stated wattage, sometimes more, at startup. My refrigerator draws around 80 watts when it's running. Even as it cycles on and off, as I watch on my Kill-A-Watt, I don't see a spike higher than 80 watts, as the increased load goes by so quickly that the meter doesn't have a chance to display it. I should be fine with a 300 watt inverter, right? If it were anything besides a big electric motor, probably, but in this instance the inverter would shut down in an overcurrent condition. To accommodate both this and the 110v load from the CPAPs, I actually need something closer to a 1000 watt inverter.

A sleep or standby function is also a useful feature in an inverter, especially in applications where power must always be available (like a refrigerator). Otherwise, it's common to just have an on-off switch- turn it on to fire up the microwave or the TV (things I would never, ever bring camping, btw), turn it off when you're done. The inverter draws power whenever it's on, whether or not there's a load present, and that can eat into your battery capacity pretty quickly. Inverters with a sleep or standby function power themselves off, wake up for a split second every few seconds to see if there's a load present, and turn themselves back on if there is. This significantly reduces their electricity consumption. The only catch here is that some very small loads may not be enough to wake up the inverter, and some refrigerators (rarely) may not check their own temperatures when there's no power present. Most inverters with a standby function allow you to adjust the trigger current draw to fix the first scenario, but since in our application we're not likely to have low current draw 110v devices in the first place it's not as critical. If you turn out to be unfortunate enough to have a refrigerator that needs constant power to function, there's a cheap and easy workaround. Velleman offers a very simple and inexpensive thermostatic switch- place the temp sensor in your fridge, and it'll operate a relay to turn on your inverter, all with very low current draw. Odds are excellent that that won't be necessary, but it's good to have a contingency plan.

OK, we've got our loads calculated, we've got our battery capacity figured out, we've selected an inverter, and now we're ready to talk about solar panels and charge controllers, since we'd like to do more than camp for one day at a time. A bunch of math aside, an excellent rule of thumb is to assume that, pretty much anywhere in North America, you'll be able to put 30 amp hours a day into your 12v battery for every 100 watts of solar panel. It'll be a bit higher in Yuma in the summer, a bit lower in Oregon in the winter, but not enough to matter unless your design is on a total knife-edge anyway. Don't do that. You'll also see folks talking about adjustable racks to precisely track angle of the sun so as to get maximum efficiency, but again, in practice this doesn't add up to more than a couple of percentage points, and if that's what it takes to make your system work you've got other problems with your design. To replace the 91 amp hours we anticipate drawing from our batteries every day, we'd need a minimum of 303 watts of solar panel capacity.

Rigid solar panels are the cheapest and most efficient, and ideally you'd mount them up off the roof to allow airflow underneath to keep them cool, which also increases efficiency. Unfortunately, all of that increases ugliness at an even higher rate, and if you were after maximum efficiency vs. beauty you wouldn't be working on a 60-70 year old trailer anyway, would you? Flexible solar panels, on the other hand, are ideal for the curved roofs on many vintage trailers, and can be completely invisible from the ground once installed. They're commonly installed to RV roofs with 3M VHB tape, sometimes with Eternabond around the edges. Being less efficient, your flexible panels will be somewhat larger than rigid panels for the same output, but generally not enough to cause issues. As with all things, manufacturers vary considerably in quality and durability, so you'll likely want to stick with a reputable manufacturer rather than the cheapest thing you find on Amazon. I chose a pair of Renogy 175w flexible panels for a total of 350 watts, which at an estimated 105 amp hours/day gives me a nice margin of error.

OK, on to the charge controller. Sure, you could just plug your panels straight into your battery, dumping in energy whether or not the battery was up to the job, but that's a bad idea for anything with more than a couple of watts of output. As added incentive, you'd also need to install a blocking diode anyway to keep your battery from discharging through your solar panels at night. 300+ watts is nothing to screw around with, so you'll need a charge controller. There are two different available technologies, since we can't make this too simple- PWM, or pulse wave modulation, and MPPT, or maximum power point tracker. Yeah, sounds complicated, but basically a PWM controller is just a fancy switch that flicks between on and off as needed by the battery, providing just above the battery voltage. This is a good, economical solution if the panels you've selected don't put out much more than battery voltage, say a maximum power voltage of 18v or so for a 12v battery.

An MPPT controller is a different animal. It intelligently drops the panel voltage down to whatever is required to efficiently charge the battery, sort of a smart DC-DC converter. As the voltage drops the current increases, which means increased efficiency- anywhere from 15% to a theoretical 20% more power can be harvested from the same panels, assuming that the panel voltage is significantly higher than the battery voltage. In this instance, the Renogy 175 watt panels operate at a maximum of 24.9v, so this is a good fit. Did I mention a 15-20% increase in harvestable energy?

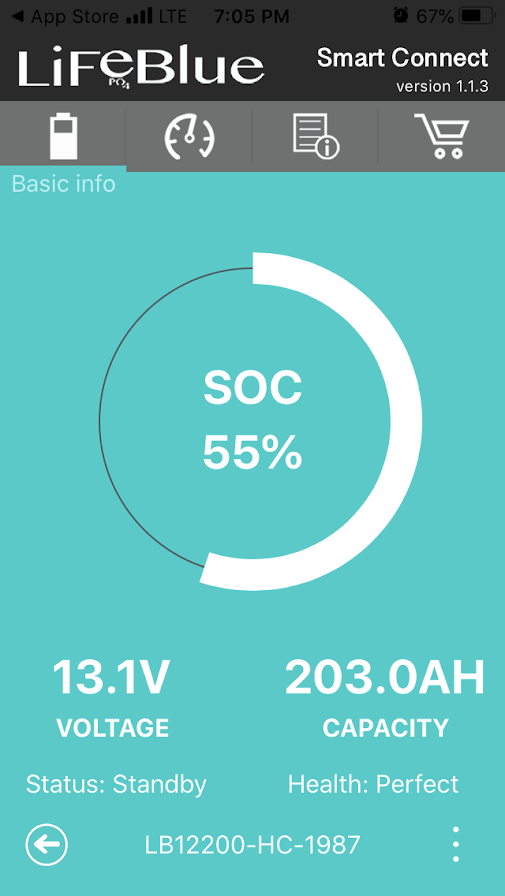

You'll want to be able to monitor all of this, of course, and keep track of how much juice is left in your battery, how much energy your solar panels are putting out, etc., etc. There are all kinds of monitoring panels sold, like you'd see in newer RVs, but they're not cheap and you'll clutter up the cool vintage vibe you're trying to create inside your old trailer. Some batteries and charge controllers have bluetooth capability, either built-in or as an add-on module, which allows you to monitor all of that on your smartphone from the comfort of your hammock while sipping a cold drink from your solar-powered refrigerator. The LifeBlue battery I chose has built-in bluetooth, and the Renogy MPPT controller I selected has an inexpensive bluetooth add-on.

Now is the moment of truth- I did all of the math, added it all up, designed my system, and, recalling that I live in Oregon and love to camp at the coast in the wintertime, when the sun is definitely in short supply, that I'm notorious for picking out the shadiest and gloomiest of all available campsites, and that I wanted enough margin to carry me through without worrying about any of that, I decided I needed a bigger margin of error. I could add additional solar panels, but since I'd already framed the new roof, placing the vent precisely where it was originally, anything beyond what I had would be visible from the ground, which is an aesthetic compromise I wasn't willing to make. I thought about bumping up to a 150AH battery, but in the end I bought a 200AH battery, enough to get me through a weekend in the unlikely event that I got zero output from the solar panels. In the worst-case scenario that I only get 50% output from my panels, I'd still be able to dry camp for four days before running into trouble. It's almost certainly overkill, but I didn't want to risk ending up with a system that was only mostly usable, and as my wife would attest overkill is pretty much my thing.